Lidaris continuous project ESPRESSO in partnership with ESA

The project ESPRESSO II is a continuation of the work on optics longevity qualification procedure with the aim to expand current knowledge for anti-reflective (AR) coatings (optical windows, wedges) operating at UV and NIR regimes in the well-controlled environment, capable to simulate low- and high vacuum ambient (up to 10-6 mbar).

The use of high-average power laser systems in space missions provides possibilities to observe, monitor, and understand complicated phenomena related to the Earth’s atmosphere. For example Aeolus. mission. Optical elements used within the laser system should withstand a considerable optical intensity load – several billions of high-energy laser pulses. If laser optics is damaged, the performance of the laser can be seriously reduced and might lead to the failure of the whole space mission. The parameter, that characterizes an optic’s ability to withstand intense laser irradiation is the so-called laser-induced damage threshold (LIDT). The LIDT depends on the working environment. Thus, in order to meaningfully characterize laser optics for space applications, the LIDT testing should be performed in a vacuum. Furthermore, many of the optical elements used in space-borne laser systems are transmissive. When intense laser irradiation passes through the transmissive optical element, damage can be induced not only on the front- but also on the back side of the optical element. The cause (failure mode) of the backside damage is rarely fully understood. There is a lack of knowledge about this important issue.

These needs are addressed in the PECS project ESPRESSO II (ESPRESSO – ESsential PREparation Steps for qualification longevity of Space Optics II) with cooperation with European Space Agency (ESA)

The project’s overall aim is to continue to carry out research and development work required to prepare reliable longevity qualification procedures. This time it is focused to evaluate transmissive high-power laser optics (AR coatings and substrates) at different irradiation conditions (355 nm and 1.6 μm) in a well-controlled vacuum environment (down to 10-6mbar) with intended use in space applications.

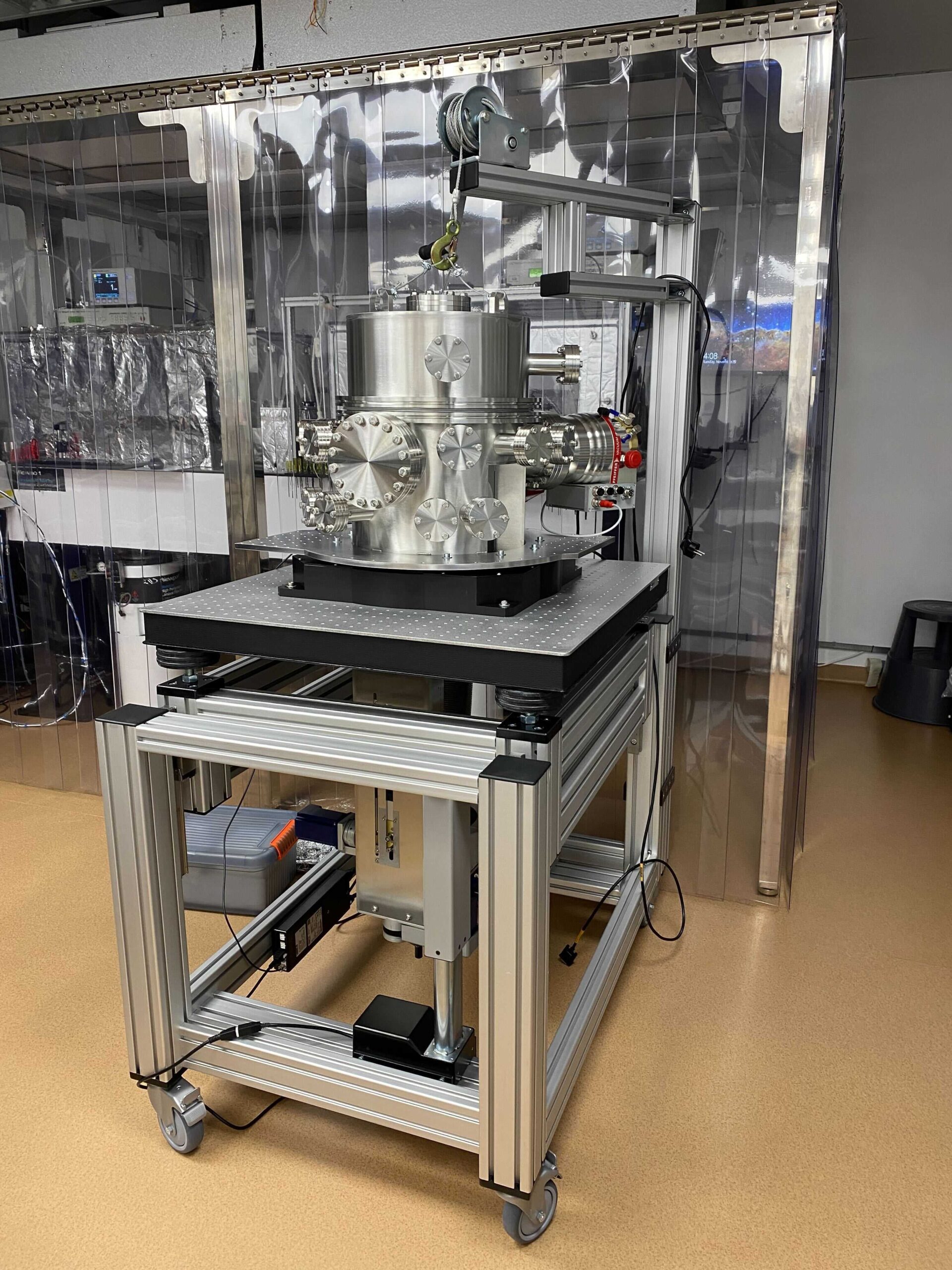

The developed vacuum system is mobile and can be attached to various laser systems, thus providing wide testing capabilities for different requirements of space missions. Testing can be performed at multiple angles (0, 22.5, 45, 56, and 65 deg.) of incidence. Furthermore, it features the capability to monitor back-side laser damage. A unique time-synchronized imaging unit is based on DIC microscopy.

Disclaimer: The view expressed herein can in no way be taken to reflect the official opinion of the European Space Agency.