Laser System Manufacturers

& Integrators

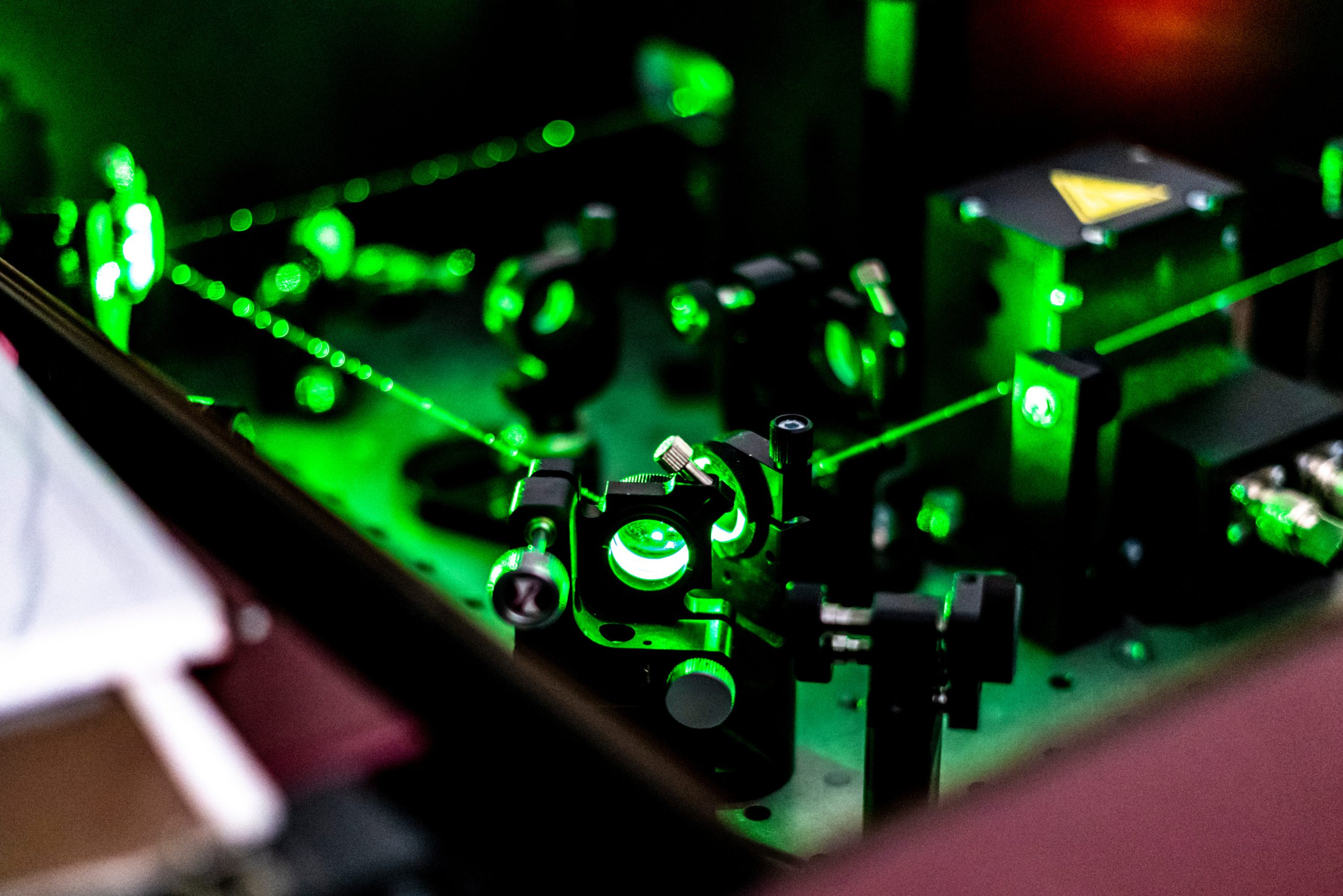

Companies building high-power lasers and laser systems must ensure the reliability of their products. Otherwise, end-users of laser systems suffer from downtime.

Lasers that often fail or need frequent maintenance cause serious damage to the reputation of the manufacturer while generating service costs for everyone.

One of the main reasons that are affecting the optical system’s performance is the quality of chosen critical optics. Environmental contamination or poor handling might also lead to similar problems. Even a single defective production batch can cause delayed problems in many products that are spread worldwide. Thus, it is better (and often much cheaper) to check optics in advance.

However, not every optics manufacturer is able or interested in showing the full picture of the damage performance of the optical element. Sometimes, there is no appropriate metrology available, or no expertise in complex laser damage phenomena topics. As there exist distinct LIDT testing approaches sometimes it is not even clear how to start specifying optics performance for a specific irradiation regime.

An inappropriate testing approach leaves some space for decision errors and manipulating LIDT numbers. Based on long years of experience LIDARIS can help in many ways to minimize the risk of optics failure. If/when your optics fail within laser – let us know: we can discuss it with you and help to interpret “why?” it might have happened. Further, we will share some strategies on how to avoid such situations in the future.

How LIDARIS

can help?

- Free support for your optics procurement and quality assurance teams: find out relevant LIDT specifications of critical optical elements for your system;

- Audit performance of your current optics suppliers: figure out if you already getting state-of-the-art optics;

- Avoid bad optics in your system by checking every production batch;

- Predict the lifetime of optical elements;

- Investigate already damaged optics to figure out where could be a potential problem.

Process

-

Collect relevant information about the critical optical elements in use

-

Let’s have a Zoom meeting (we can sign NDA if needed) and analyze your situation

-

Getting familiar with your optics and getting relevant from screening experiments

-

Identify potential ways or strategies of avoiding damage in your systems

About

Lidaris

-

20+ YearsOf experience with Laser Damage Subject

-

20+ R&D ProjectsCompleted and Still Strong in A Long-Term Partnership

-

85% Exportto United States, European Union, Asia

-

150+ CustomersWorldwide Organizations, Who Trusts Us with Their Needs

-

16 Peoplein a Professional Team of Lidaris

-

3 PhD’sWith Doctorates in Laser Damage Subject

Related tests

Show all-

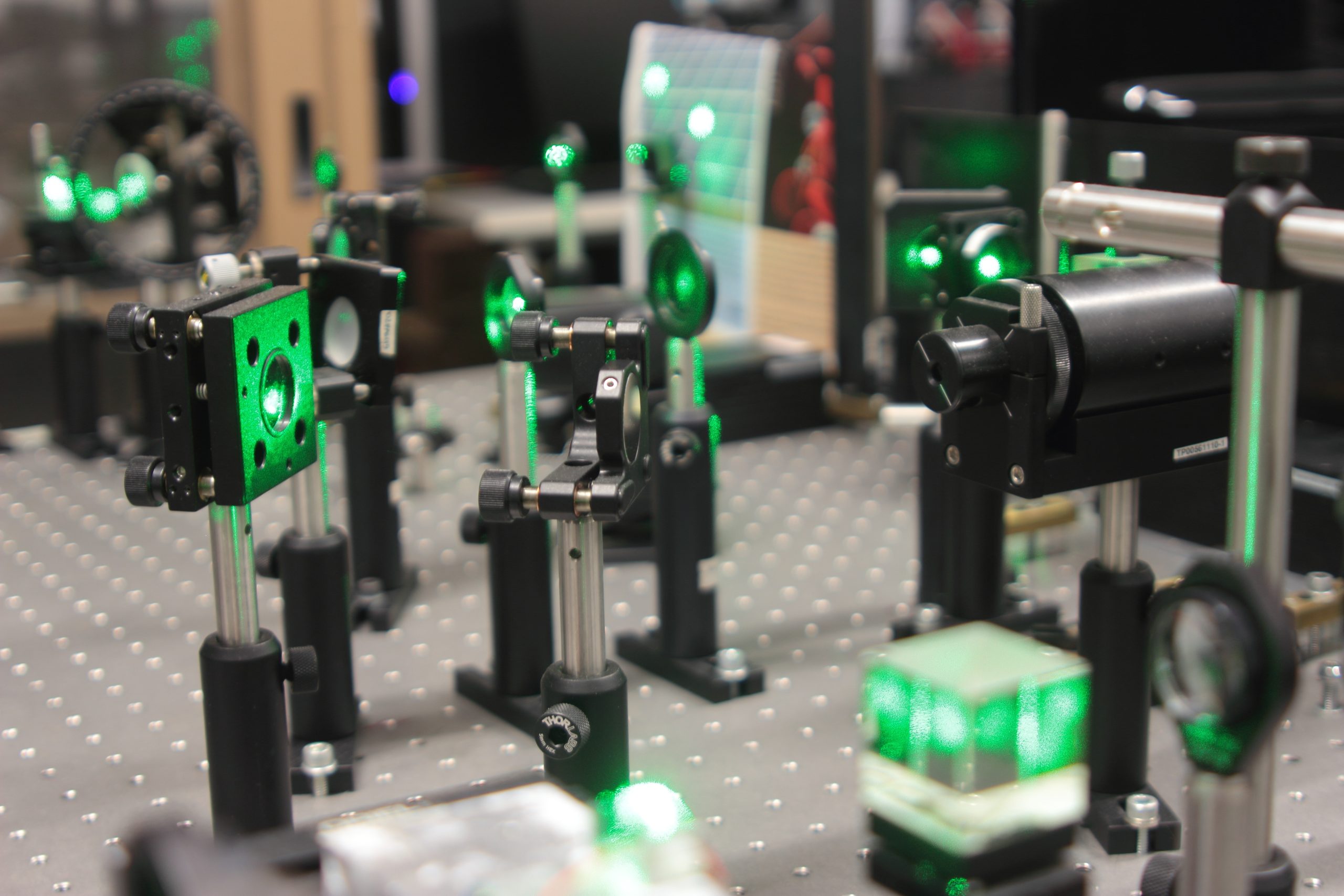

ISO S-on-1

LIDT test (21254-1,2)The most popular technique used for laser-induced damage threshold (LIDT) characterization of laser optics.read more -

Raster scan

LIDT testIt characterizes the worst-case scenario when it comes to large optics and defect-driven damageread more -

"Classical"

Lifetime TestThis test is available at ps, fs pulse duration and @kHz repetition rates: allows to investigate LIDT, ageing and lifetimeread more -

Photothermal Common-path Interferometry absorptance testBasic Photothermal Common-path Interferometry absorptance test packread more

more services

Show all-

For Manufacturers

We will assist you with:

- Partnership in optics R&D projects

- Quality checking of production batches

- Root cause analysis of Optics Failure

Find out more › -

For Distributors

We will assist you with:

- LIDT testing/certification in: CW-NS-PS-FS, From IR to UV, Air and vacuum

- Benchmark: Vendors, Competitors, Batches/items

Find out more › -

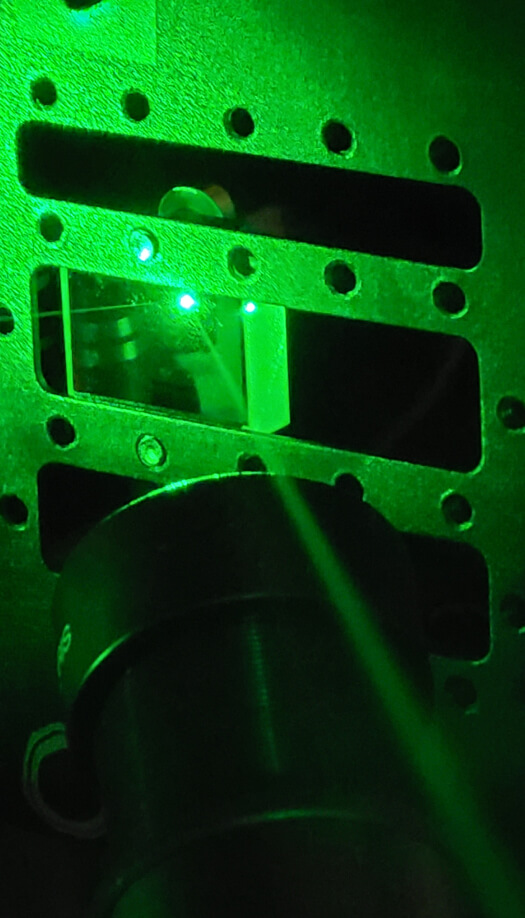

For Integrators

We will assist you with:

- ISO based and custom LIDT tests for high throughput screening of non-viable optics

- Optics lifetime testing

- Other tests: Low-loss absorption, Thermovision, Wavefront sensing

Find out more › -

For Project Matters

We will assist you with:

- Case studies of laser damage in optics: finding a problem

- Planning R&D projects and choosing appropriate test methods

- Quantitative feedback by testing

- Interpretation of measurement results

Find out more ›