Laser Optics Sales

& Distribution

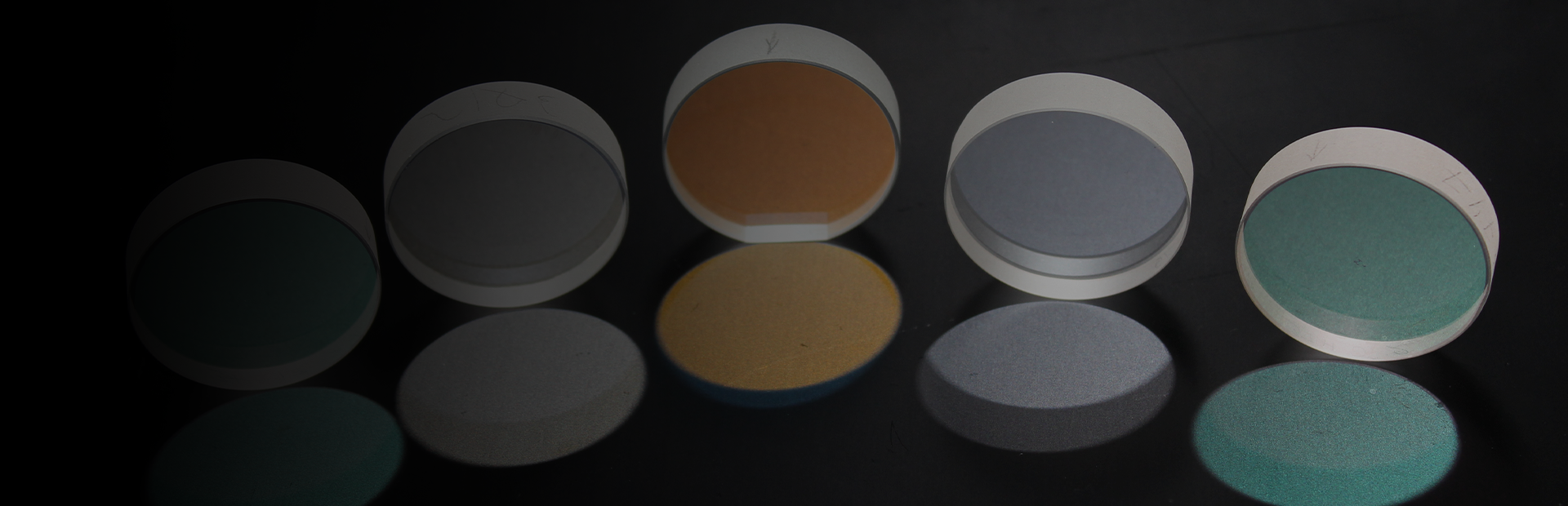

“Catalog optics” companies that sell or distribute various optical elements are also held responsible for specifying and ensuring the quality and performance of what is being sold. Interestingly, there might be more than one vendor for every position in an optics catalog.

Accordingly, production quality might vary from vendor to vendor or batch to batch and thus cause many problems down the supply chain. By feeling that the end-users of high-power laser optics often don’t want to risk and thus avoid buying optics without proof of quality.

However, not all laser optics vendors can check their products by the means of laser damage performance or provide relevant LIDT numbers to the end customer. Also, some customers need to specify LIDTs under non-standard use conditions and it is not easy to find such characterization service.

Furthermore, customers often want to be consulted on complex laser damage-related questions before making the purchase. This complicates the whole optics sales process.

Finally, optics characterization itself does not guarantee a sale as low LIDT numbers can prevent purchases.

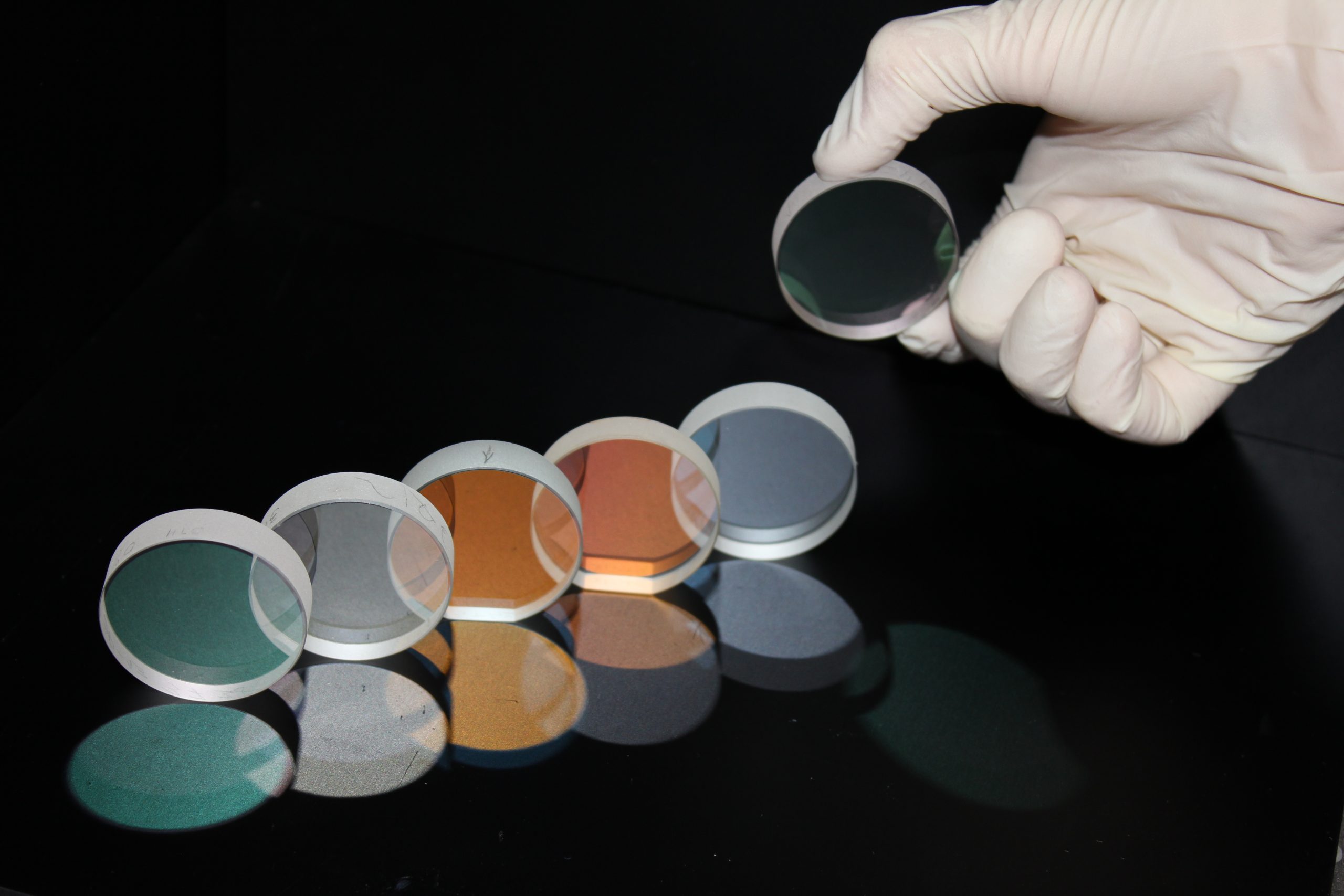

Over 10 years LIDARIS has intensively worked with large optics sales and distribution companies worldwide and is well familiar with this kind of laser damage issue. There are at least two ways in which optics distributors can benefit from laser damage testing.

Firstly, finding the best manufacturing technology or vendor and knowing that your optics feature high LIDT values, provides a unique selling point and serves as great marketing material. But for these results to be trusted, they should be determined by an independent metrology lab.

Secondly, the low LIDT values are not always a problem. Not everyone needs extremely high LIDT values sometimes it is enough to know a safe operational limit as no one wants their optics to break unexpectedly. To guarantee quality pass/fail certification tests can be done for every production batch.

Currently, 140 companies worldwide trusted Lidaris to test their optics performance. For large quantities of testing a dedicated service is possible, which handles speed and high-throughput testing capabilities.

How LIDARIS

can help?

- Free consulting in understanding laser damage specifications;

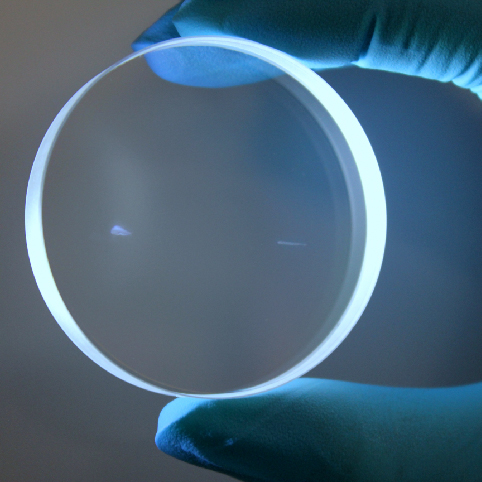

- ISO standard-based and customized laser damage (LIDT) testing at various irradiation conditions;

- Fast turnaround for standard testing;

- Pass/fail certification testing;

- Detailed reports and customer support;

- Contract-based dedicated service (customized testing systems, testing protocols, measurement reports);

- Testing bundles (LIDT testing combined with absorption, scattering, thermal sensing and other).

Process

-

Tell us about samples that you have and tests that you need via the my.lidaris.com platform

-

Get a quote for testing service (sign NDA if needed)

-

Prepare your samples and ship them to LIDARIS

-

Get quantitative feedback: measurement report

-

Discuss the meaning of the results if needed

About

Lidaris

-

22+ YearsOf experience with Laser Damage Subject

-

20+ R&D ProjectsCompleted and Still Strong in A Long-Term Partnership

-

85% Exportto United States, European Union, Asia

-

150+ CustomersWorldwide Organizations, Who Trusts Us with Their Needs

-

18 Peoplein a Professional Team of Lidaris

-

3 PhD’sWith Doctorates in Laser Damage Subject

Related tests

Show all-

ISO S-on-1

LIDT test (21254-1,2)The most popular technique used for laser-induced damage threshold (LIDT) characterization of laser optics.read more -

Raster scan

LIDT testIt characterizes the worst-case scenario when it comes to large optics and defect-driven damageread more -

"Classical"

Lifetime TestThis test is available at ps, fs pulse duration and @kHz repetition rates: allows to investigate LIDT, ageing and lifetimeread more -

Photothermal Common-path Interferometry absorptance testBasic Photothermal Common-path Interferometry absorptance test packread more

more services

Show all-

For Manufacturers

We will assist you with:

- Partnership in optics R&D projects

- Quality checking of production batches

- Root cause analysis of Optics Failure

Find out more › -

For Distributors

We will assist you with:

- LIDT testing/certification in: CW-NS-PS-FS, From IR to UV, Air and vacuum

- Benchmark: Vendors, Competitors, Batches/items

Find out more › -

For Integrators

We will assist you with:

- ISO based and custom LIDT tests for high throughput screening of non-viable optics

- Optics lifetime testing

- Other: Low-loss absorption, Thermovision, Wavefront sensing

Find out more › -

For Project Matters

We will assist you with:

- Analysis and sales of the resistance of optical materials

- Technical consultations on laser optic questions

- Discovering new and improving old measuring scientific work

Find out more ›