When an optical sample is exposed to intense laser radiation, it might become damaged.

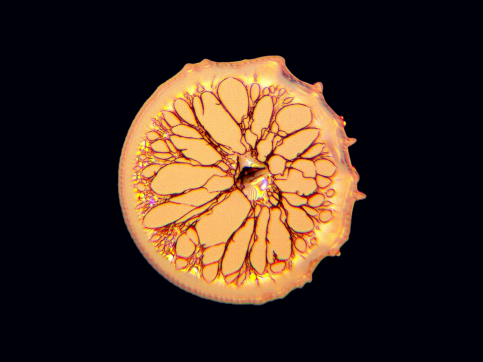

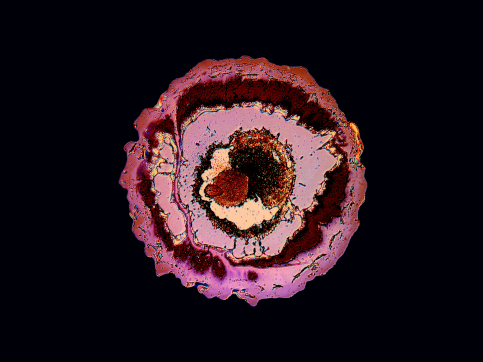

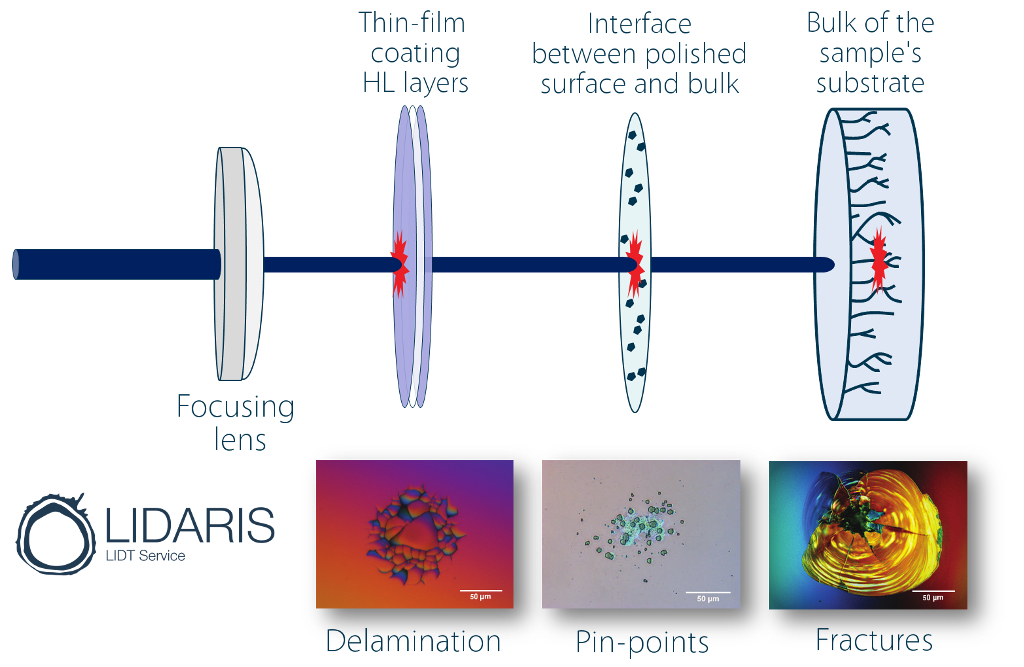

Laser-Induced Damage (LID) is understood as an irreversible modification of the material’s properties caused by the surface or bulk melting, material softening and bending, cracking, pitting, vaporization or violent shattering. According to the International Standard Organization (ISO), it is defined as:

“…any permanent laser radiation induced change of the surface characteristics of the specimen which can be observed by an inspection carried out with an incident light microscope having Nomarski-type differential interference contrast. A magnification in the range from 100X to 150X shall be used [1]. ”

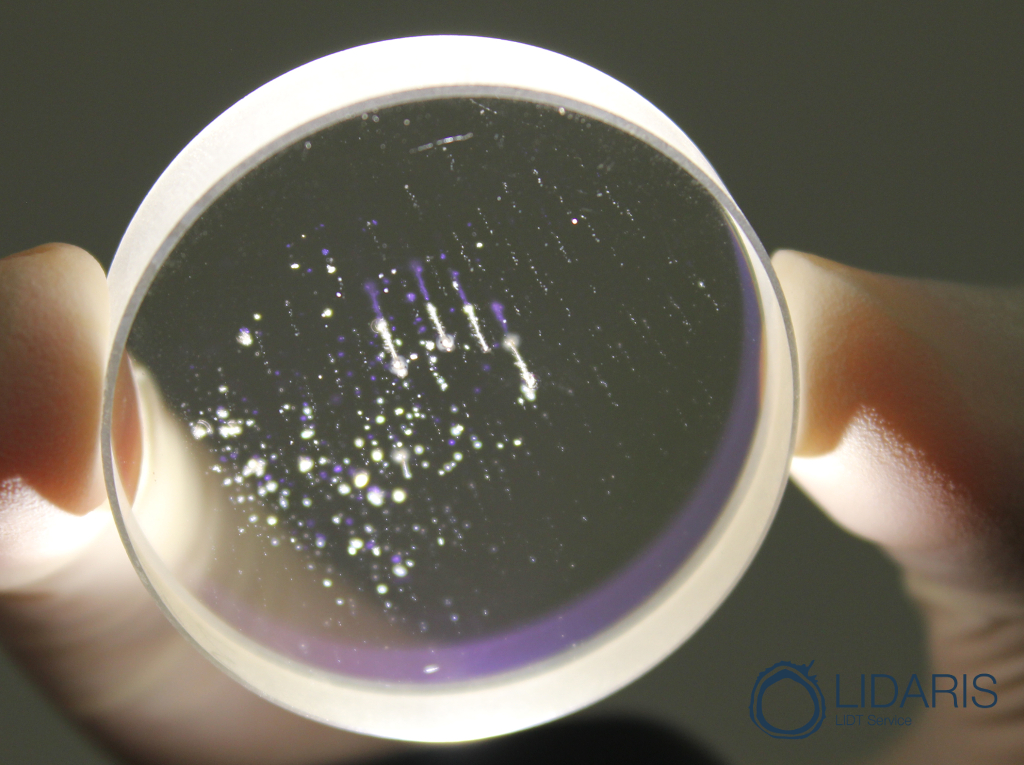

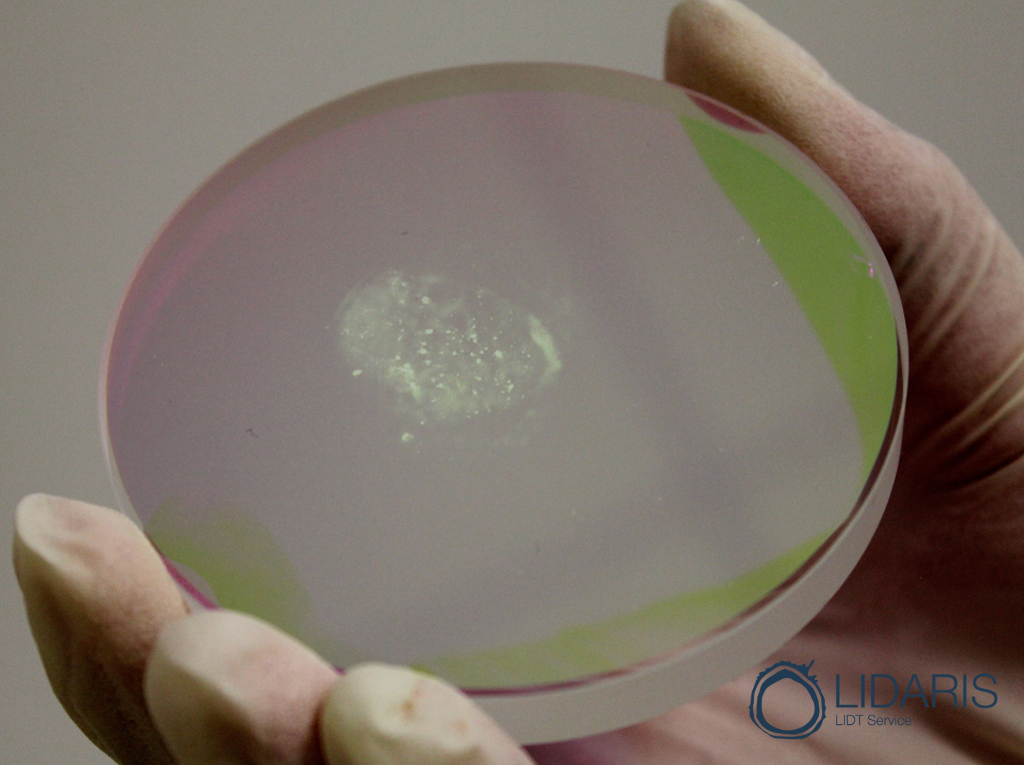

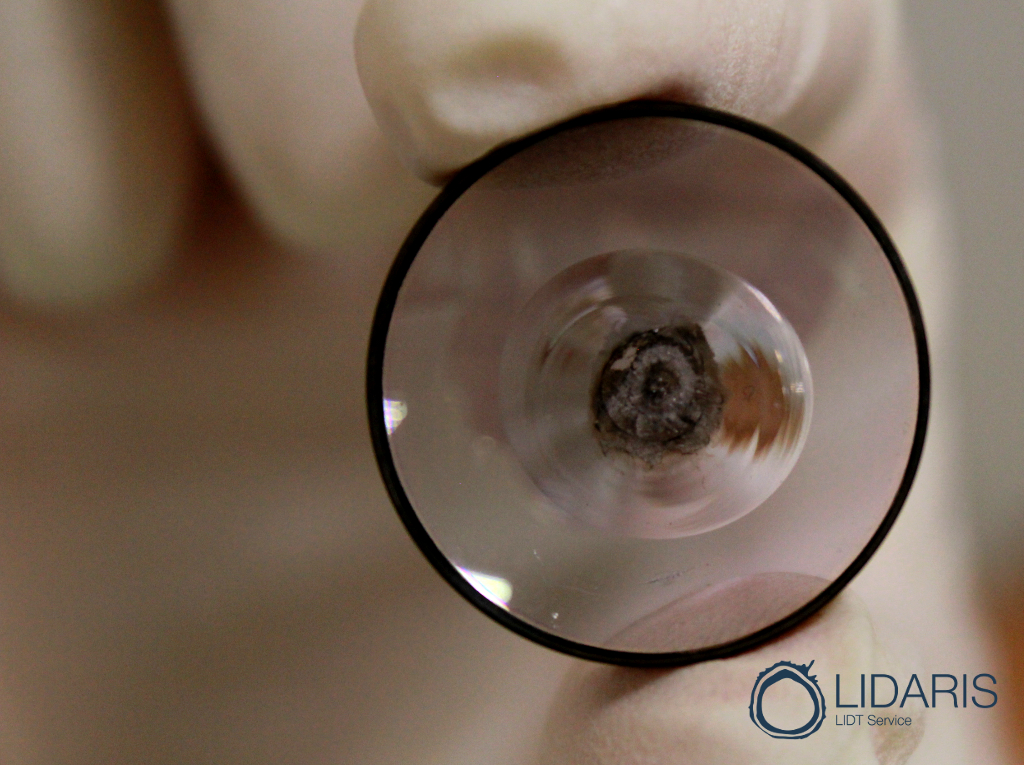

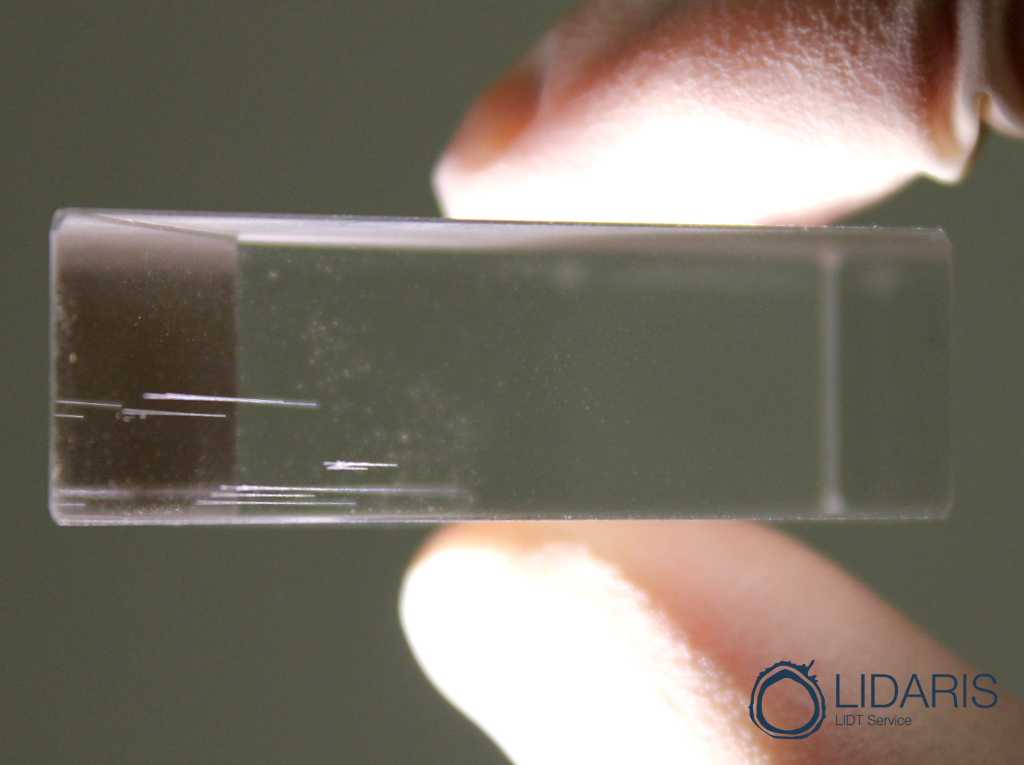

Examples of laser-induced damage on the optical elements:

Laser-Induced Damage varies and depends on various parameters:

Laser irradiation parameters:

- Wavelength;

- Pulse Duration;

- Spatial beam profile;

- Temporal pulse profile;

- Repetition rate and etc;

Environment conditions:

- Air;

- Vacuum;

- Temperature;

- Contamination and etc;

Material properties:

- Defects

(intrinsic and extrinsic); - Preparation method

(polishing, annealing); - Shape and etc.;

Laser-induced damage might form in the different locations: bulk material, on the surface of a sample or within an optical coating. Laser-induced damage morphology is highly associated with damage mechanism and gives a “rough idea”, what causes the optical element to break. Read more on this topic here.

Since the physical mechanism of laser-induced damage depends on so many variables and conditions, up to now we still do not fully know how optical elements are damaged. What triggers damage occurrence and how it can be avoided or improved? Thus, laser-induced damage remains one of the most important issue limiting high-power laser optics development for more than 50 years.

What is known for sure, if you want to improve something – you should measure it. In the case of laser-induced damage you should test optical elements for laser damage at the conditions they are intended to be used. Contact Lidaris expert’s about testing possibilities and learn more about the ways to survive laser damage.

Reference

Characterization of laser-induced damage is described by ISO:21254-1,2,3 standards:

[1] Lasers and laser-related equipment – test methods for laser-induced damage threshold- Part 1: Definitions and general principles (ISO 21254-1:2011).

[2] Lasers and laser-related equipment – test methods for laser-induced damage threshold- Part 2: Threshold determination (ISO 21254-1:2011).

[3] Lasers and laser-related equipment – test methods for laser-induced damage threshold- Part 3: Assurance of laser power (energy) handling capabilities (ISO 21254-1:2011).

If you are interested in laser-induced damage phenomena we also highly recommend to read:

[4] D. Ristau, Laser-Induced Damage in Optical Materials (CRC press, Taylor &Francis Group, Florida, 2014).

[5] R. M. Wood, Laser damage in optical materials (A. Hilger, Bristol, 1986)