ISO 1-on-1 LIDT test (21254-1,2)

1-on-1 test explained:

Use this test for:

- a feedback when optimizing polishing process and characterizing high defect densities;

- investigation of intrinsic material properties;

- screening experiments;

- reference, when quantifying “fatigue” or “conditioning” effects;

Test description

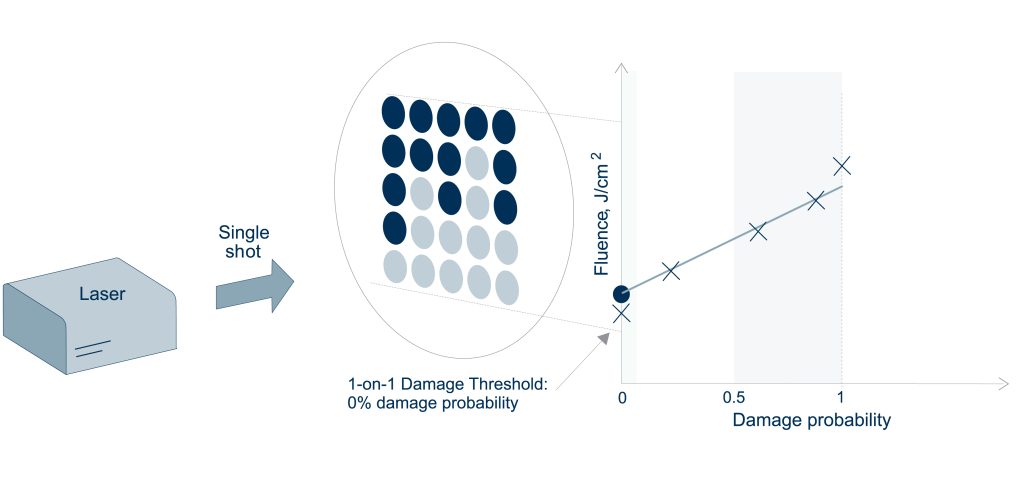

The entrance surface of an optical element is divided into a matrix of test sites. Each test site is then exposed to a single laser pulse using fixed laser irradiation level (peak fluence). Distinct irradiation levels are used for individual test sites. After exposure, the status of all test sites was inspected using offline microscopy. Collected damage statistics are interpreted to calculate damage probability versus applied laser irradiation level. Using this data set laser-induced damage threshold (LIDT) is calculated as the maximum applied laser irradiation level featuring zero damage probability. In the case of CW irradiation, the 1(Time)-on-1 test can be repeated using different pulse duration.

Known limitations and risks:

- 1-on-1 LIDT might be overestimated

- when optical element features very low defect density, rare defects will be simply missed by small laser beam (use raster scan LIDT tests instead)

- Ageing, fatigue or incubation effects are not considered;

- Annealing of neighboring test sites is possible at the CW regime;

Most popular test parameters for this test

| Wavelength | Pulse duration(1) | Pulses per test site | Interested? |

| 1070 nm | 30 s | 1 | ORDER |

| 355 nm | 5 ns | 1 | ORDER |

| Custom | Check all availability or configure your own at my.lidaris.com | ||

(1) effective pulse duration measured at Full Width Half Maximum

Testing

conditions

Related tests

Show all-

ISO S-on-1

LIDT test (21254-1,2)The most popular technique used for laser-induced damage threshold (LIDT) characterization of laser optics.read more -

Raster scan

LIDT testIt characterizes the worst-case scenario when it comes to large optics and defect-driven damageread more -

ISO LIDT Certification Test (21254-1,3)This technique is designed to separate good and bad optics when end-use irradiation conditions are knownread more

ISO LIDT Certification Test (21254-1,3)This technique is designed to separate good and bad optics when end-use irradiation conditions are knownread more -

R-on-1

LIDT testTesting protocol, which provides preliminary information about the LIDT of the surface-limited samplesread more

Test bundles and packages

-

Find out more ›

Optics Characterization Bundle for CW regime at 1070 nm

The testing package consists of multiple tests, which are carefully selected to address optics characterization issues at the CW regime. -

Find out more ›

Lifetime + Certification Bundle for Industrial Grade fs-ps Laser Optics

The package consists of several tests carefully selected to address optics certification for critical applications.

more tools

and useful information

-

Find out more ›

Testing conditions

Check out all available laser damage testing conditions (wavelengths, pulse regimes, environments, and more). -

Find out more ›

Laser Damage infobase

Check out a useful glossary of terms and simple explanations related to the main topics of laser damage terminology. -

Find out more ›

Online Fluence calculator

Check out a calculator equipped with laser-related calculus that is frequently required in practice: such as laser fluence. -

Find out more ›

Downloads and docs

Here you can download all information about laser damage testing available at Lidaris. -

Find out more ›

New client guide

Here you will find usefull guidlines and suggestions for everyone, who is new the laser damage field. -

Find out more ›

Orders FAQ

Fast way to find out about test samples prepration, handling, and shipping